FishBytes: FISH SILAGE

Fish silage is a liquid product made from whole fish or parts of fish that are liquefied by the action of enzymes in the fish, in the presence of an added acid. The enzymes break down fish proteins into smaller soluble units, and the acid helps to speed up their activity while preventing bacterial spoilage.

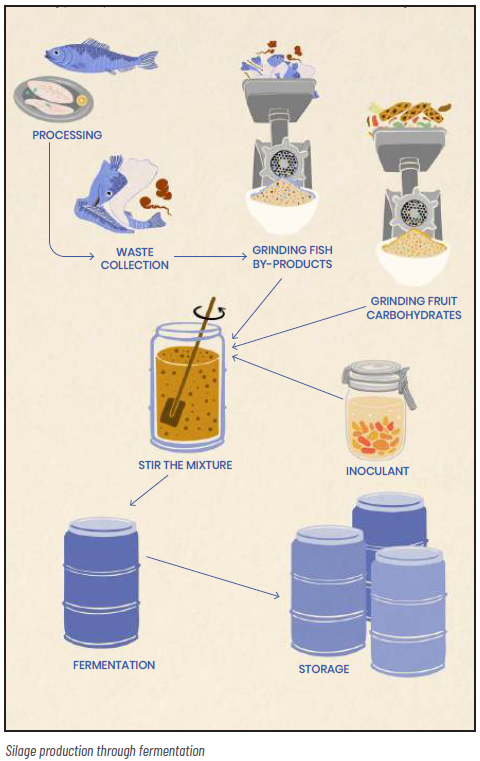

There are two known methods of fish silage production, using either fermentation or by adding acid. Fish silage can be produced by fermentation using lactic acid bacteria. The raw material must be minced and mixed with fruit waste, or another source of sugar, and an acid-producing bacteria (the inoculant) like Lactobacillus plantarum as a starter culture.

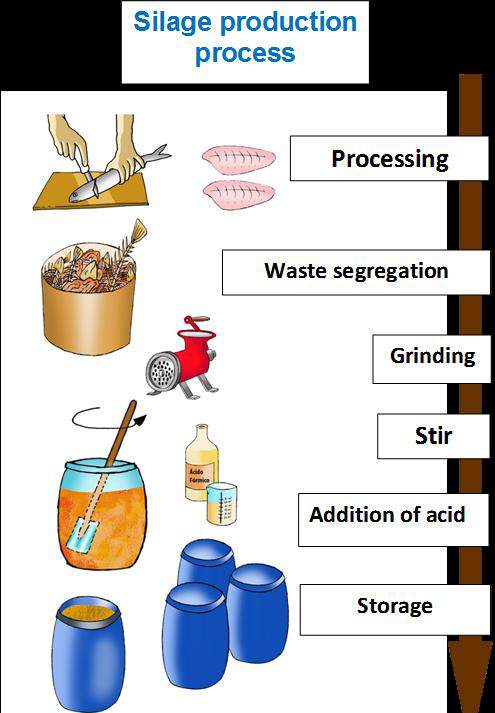

Acid preservation is a simple and inexpensive way to preserve by-products from processing. Formic acid (typically 2-3% w/w) is considered a good choice since the silage made with it is not excessively acidic (ideally 3.5) and therefore does not require neutralisation before being used. Furthermore, organic acids have antimicrobial and antifungal properties, acting both as bacteriostats and bacteriocides.

- The raw material is first minced; suitably small particles can be obtained by using a hammer mill grinder fitted with a screen containing 10 mm diameter holes.

- An organic acid (e.g. formic acid) is added in the ratio of 35 kg or about 30 litres of acid to one tonne of fish, and mixed thoroughly. The acidity of the mixture must be pH 4 or lower to prevent bacterial action. After the initial mixing, the silage process starts naturally, but occasional stirring helps to ensure uniformity.

- The production tank can be of any size or shape provided it is acid resistant. Concrete tanks treated with bitumen are suitable for holding large quantities.

- The rate of liquefaction depends on the type of raw material, its freshness, and the temperature of the process. Most species can be used, but sharks and rays are rather difficult to liquefy, and should be mixed in with other species. Fatty fish liquefy more quickly than white fish offal, and fresh fish liquefy much more quickly than stale fish.

- The warmer the mixture, the faster the process; silage made from fresh white fish offal takes about two days to liquefy at 20°C, but takes 5-10 days at 10°C, and much longer at lower temperatures. Temperatures should optimally be between 5 and 40 degrees Celsius.

- Once the silage is prepared it can be handled like any other liquid, and transported in bulk or in containers.

How does it differ from fishmeal?

What are the uses of fish silage?

- As a nutrient-dense product ideal for feed purposes, or for eventual use as a fertiliser. The nutrient composition is, in practice, the same as the raw material used for silage production, and comparable to the nutrient composition of fishmeal on a dry matter basis;

- A feed input for aquaculture, or for chicken, pork and other livestock production. Its use as a feed ingredient or as a protein source has resulted in improved feed intake, better growth and the improvement of some performance indicators in livestock industries;

- Due to its relatively low acidity, fish silage can be fed directly without any prior mixing and treatment; or it can be mixed with dry feed ingredients such as grains and then be given directly to livestock as wet feed;

- Can also be used in pellet production and extruded feeds; in fact, the inclusion of silage often results in extruded pellets being stronger and more resistant than without silage;

- Reduces the spread of pathogenic microorganisms found in dead fish or fish killed for disease control, owing to the antimicrobial properties of the organic acids; and

- May be used as a fertiliser if it does not meet the quality requirements for feed purposes. It is a good source of nitrogen (from the protein), phosphorus, potassium, calcium, and magnesium (particularly from the bone structure) and most trace elements needed for plants.

Is fish silage technology suitable for all fishing communities?

Before the technology is introduced in fishing communities at the smallscale level, a more detailed study should be conducted, including:

- availability of raw materials;

- collection and storage of raw materials;

- availability and use of the acid required;

- availability of facilities and equipment; and

- the potential market and demand for the produced fish silage.

References

- Toppe, J., Olsen, R.L., Peñarubia, O.R. & James, D.G. 2018. Production and utilization of fish silage. A manual on how to turn fish waste into profit and a valuable feed ingredient or fertilizer. Rome, FAO. 28 pp. http://www.fao.org/3/i9606en/I9606EN.pdf

- Toppe, J. and Olsen, R.L. 2024. Fish silage production by fermentation – A manual on how microbial fermentation can turn fish waste into a valuable feed ingredient or fertilizer. Rome, FAO. https://doi. org/10.4060/cd0799en

- Islam, J., Yap, E.E.S., Krongpong, L., Toppe, J. and Peñarubia, O.R. 2021. Fish waste management – An assessment of the potential production and utilization of fish silage in Bangladesh, Philippines and Thailand. FAO Fisheries and Aquaculture Circular No. 1216. Rome. https://doi. org/10.4060/cb3694en