Article II 6/2025 - HANDLING WASTE FROM TILAPIA PROCESSING: STRATEGIES AND SOLUTIONS

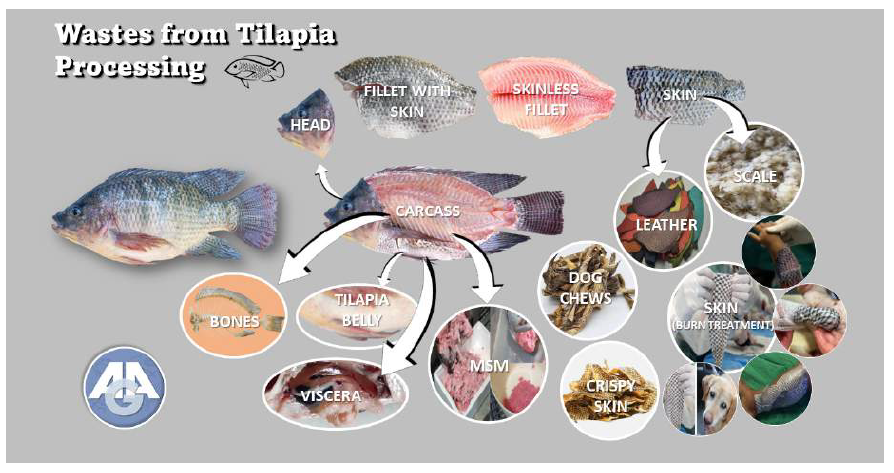

Despite these advances, tilapia processing continues to discard millions of tonnes of waste annually. Processing generates 30–45% of the fish’s weight in waste, including heads, bones, skin, viscera, fins and scales. These materials are rich in nutrients and bioactive compounds but are often discarded. When handled under hygienic, low-temperature conditions, they can be transformed into high-value products that contribute to sustainability and the circular economy.

The potential applications are diverse. Not only is tilapia skin used to produce high-quality leather, but it is also rich in collagen and gelatin. This makes it useful in the biomedical, pharmaceutical, and food industries. The scales and bones provide hydroxyapatite and chitin, which can be processed into chitosan for use in water purification, biodegradable packaging, and drug delivery systems. Viscera yield enzymes and oils with nutritional and industrial uses. Other derivatives include fishmeal, protein hydrolysates, fish oil, biodiesel, glue, and bioactive compounds for the nutraceutical and cosmetic sectors.

Recognising these byproducts as valuable resources reduces environmental impact, creates new revenue streams, promotes innovation, strengthens food security, and meets the growing consumer demand for sustainable seafood.

_____________________________________________________________

¹ GLOBEFISH | Quarterly Tilapia analysis - August 2025

Human food applications

Tilapia skin is gaining popularity in Brazil as a sustainable, nutritious food ingredient. When prepared as pururuca, the skin is seasoned and fried to create a crispy, savoury snack. This practice reduces food waste and provides a source of high-quality protein and collagen. Culinary experts have showcased recipes featuring tilapia skin, demonstrating its versatility in both traditional and innovative dishes.

Chocolate cookies and enriched cakes

Fish bones are rich in calcium, phosphorus and protein, making them promising ingredients for fortifying food products. Fish bone meal can improve the nutritional value of snacks, such as cookies, by increasing their calcium and protein content. Additionally, chocolate-flavored cakes enriched with mechanically separated meat (MSM) contain higher levels of protein, lipids and ash. Technologically, higher MSM concentrations reduce hardness, chewability, elasticity and cohesiveness while increasing adhesiveness. Sensory analysis indicates that cakes containing up to 8% MSM are highly acceptable, confirming the feasibility of incorporating low levels of MSM into nutritious products.

Industrial applications

Filleting wastes can account for up to 60% of a fish’s weight and still contain significant amounts of edible muscle tissue. The meat from tilapia carcasses is rich in protein and fat. It can be used to make sausages, surimi, protein concentrates, and breaded products, such as nuggets. This approach reduces environmental burden and production costs while adding value to aquaculture byproducts.

Biodiesel and fishmeal

Tilapia processing waste can be converted into biodiesel and fishmeal. Large-scale production is technically feasible and financially profitable. It has a net present value of around USD13.89 million and a return on investment within three years. However, smaller facilities face challenges due to transportation and logistical costs, highlighting the need for optimised operations and technological innovations.

Fish protein hydrolysates

Tilapia processing wastes can be processed into protein hydrolysates rich in bioactive peptides. These compounds have applications in functional foods, animal nutrition, and dietary supplements. Their production not only promotes sustainability but also adds value to the aquaculture chain.

Aquaculture feed

Tilapia processing wastes are a rich source of protein and nutrients. Converting these byproducts into tilapia waste meal provides high-quality protein for farmed species, reducing reliance on conventional fishmeal and supporting sustainable feed production in line with circular economy principles.

Tilapia skin in dog chews

Tilapia skin can also serve as a single-ingredient chew for dogs. Fully digestible and nutrient-rich, these chews support dental health, a shiny coat, and overall well-being. Their natural fish aroma makes them highly palatable to pets.

Biomaterials and functional ingredients

Biomedical applications of fish scales

Tilapia scales contain hydroxyapatite, a valuable mineral used in bone regeneration, implants, and tissue engineering. Combined with polymers such as high-density polyethylene, the scales yield biocompatible composites with improved mechanical properties. They also provide bioactive glycosaminoglycans such as chondroitin sulfate, with anticoagulant and anticancer applications. Transforming scales into functional biomolecules merges sustainability with medical innovation.

Chitosan from tilapia scales

Scales are a source of chitin and chitosan, versatile biopolymers with uses in pharmaceuticals, agriculture, food preservation, cosmetics, water treatment, and biodegradable packaging. Valorising scale waste reduces environmental impacts and provides renewable alternatives to synthetic materials.

Calcium phosphates from carcasses

Tilapia carcass waste, consisting mainly of bones, contains high levels of calcium phosphate, including hydroxyapatite and tricalcium phosphate. These phosphates are essential for biomedical applications such as bone regeneration. Producing biphasic calcium phosphate (BCP) nanomaterials from tilapia waste creates high-value, stable, and bioactive biomaterials for orthopedic and dental applications.

Biosurfactants from viscera wastewater

Wastewater from tilapia viscera contains proteins, lipids, and nutrients that support microbial production of biosurfactants. These biodegradable and biocompatible compounds are stable under extreme conditions, making them ideal for industrial applications and promoting circular economy practices.

Tilapia skin in burn treatment

Tilapia skin has emerged as a viable option for burn treatment. Its high collagen content and structural similarity to human skin make it an effective biological dressing. Studies show that tilapia skin promotes faster healing, reduces pain, and lowers infection rates compared to traditional treatments. This cost-effective method has been successfully applied in both human and veterinary medicine.

Tilapia skin membrane restores corneal damage in dogs

An innovative surgical approach is showing promising results in restoring vision in dogs with corneal ulcers and severe eye injuries, including perforations. This technique uses a collagen-rich biocuration membrane derived from tilapia skin for tissue repair. Applied as a graft, the skin acts as a biological dressing, stimulating corneal re-epithelialisation and accelerating healing. This biotechnology represents a significant advance in veterinary ophthalmology.

Conclusion

By adopting circular economy principles, the tilapia industry can transform residues (wastes) into high-value products such as functional foods, animal feed, biodiesel, protein hydrolysates, gelatin, chitosan, and advanced biomaterials for biomedical and pharmaceutical uses.

Recognising and harnessing this potential reduces environmental impacts, fosters sustainable resource management, creates new revenue streams, promotes innovation, and strengthens food security. Integrating waste recovery into tilapia processing shows that aquaculture can be economically profitable and environmentally responsible.

Ultimately, treating tilapia byproducts as resources rather than waste paves the way for a more sustainable, efficient, and circular seafood industry.

References

Bacelar, R.G.A. et al. Mechanically separated meat prepared with edible tilapia filleting waste from a public fish market. Acta Scientiarum. Animal Sciences, 45: e60993, 2023.

Corrêa, T.H.A & Holanda, J.N.F. Recycling of tilapia carcass waste to obtain nanostructured biphasic calcium phosphate powder. Cerâmica, 69(392): 261-265, 2023.

Costa, E.R.C. et al. Tilapia viscera wastewater: an innovative substrate for sustainable biosurfactant production by Penicillium citrinum UCP 1183. Brazilian Journal of Environmental Sciences, 60: E2524, 2025.

Figueiredo, A.F. et al. Enrichment of chocolate-flavored cake with the addition of minced fish flour derived from nile tilapia processing. Revista Observatório de la Economía Latinoamericana, 23(4): 01-24. 2025.

Gonçalves, T.M. et al. Evaluation of characteristics of carcass of Nile tilapias (Oreochromis niloticus) in four classes of abate weight. Acta Scientiarum. Animal Sciences, 25(1): 25-29, 2003.

Igansi, A.V. et al. Biodiesel and fishmeal from Nile tilapia waste: process, techno-economic, and Monte Carlo analyses. Biofuels, Bioprod. Bioref., 18: 70-86, 2024.

Kristanty, R.E. et al. Isolation and Characterization of Chitosan from Tilapia Fish Scale (Oreochromis niloticus). IOP Conf. Ser.: Earth Environ. Sci., 1482: 012029, 2025.

Moura, H.C. et al. Obtaining glycosaminoglycans from tilapia (Oreochromis niloticus) scales and evaluation of its anticoagulant and cytotoxic activities. Food Research International, 140: 110012, 2020.

Nurhayati, A.P.D. et al. Utilization of fish-processing waste as replacement of fish meal in aquafeed. BIO Web of Conferences 157: 01002, 2025.

Nurilmala, M. et al. Characteristics of tilapia fish scale gelatin and its application in surimi. BIO Web of Conferences 112, 09001, 2024.

Otwey, R.Y. et al. Assessment of waste generated from fresh Nile tilapia Oreochromis niloticus in Accra, Ghana. Aqua. Fish & Fisheries, 4:e188, 2024.

Peng, J. et al. Effect of extraction methods on the properties of tilapia scale gelatins. International Journal of Biological Macromolecules, 221: 1150-1160, 2022.

Silva, J.F.X. et al. Utilization of tilapia processing waste for the production offish protein hydrolysate. Animal Feed Science and Technology, 196: 96– 106, 2014.

Sousa, P.S. et al. Sustainable biofuel production from fish processing waste: lipase-catalyzed hydroesterification of tilapia residual oil. Biofuels, Bioprod. Bioref., 2799, 2025.

Souza et al. Preparation of Nile tilapia (Oreochromis niloticus) waste meal for human consumption. Ciência Rural, 54:09, e20220626, 2024.

Souza Filho, M.S.M. et al. Obtenção e Caracterização de Gelatina de Pele de Tilápia-do-nilo (Oreochromis niloticus) em Escala Piloto. Fortaleza: Embrapa Agroindústria Tropical, 19 p., 2017.

Souza, M.L.R. et al. Inclusion of protein concentrates from marine and freshwater fish processing residues in cereal bars. International Journal of Latest Research in Science and Technology, 6(2): 1-4, 2017.