Article II 3/2024: SUPER-COOLING THE FISH SUPPLY CHAIN

It has long been known that lower temperatures will improve storage life and retain quality for a longer duration. However, if any freezing is to be avoided, the lowest temperature that can be used is believed to be the freezing point of the fish, typically between -0.5°C and -1.5°C. To achieve a longer storage life, fish may be frozen, but there is a perception that freezing adversely affects quality and that ‘never previously frozen’ is synonymous with a higher quality. Thus, processors and exporters have looked to find a way of increasing the storage life of fish without fully freezing the fish. This presents significant opportunities for changing the supply of fresh fish to market.

Super-cooling defined

It is possible to take food below its freezing point without any ice being formed. While the super-cooling mechanism in pure liquids, such as water, is attributed to the lack of a seed crystal or nucleus around which an ice crystal can form during freezing, it is less clear how super-cooling occurs in more complex liquids and solids, such as fish.

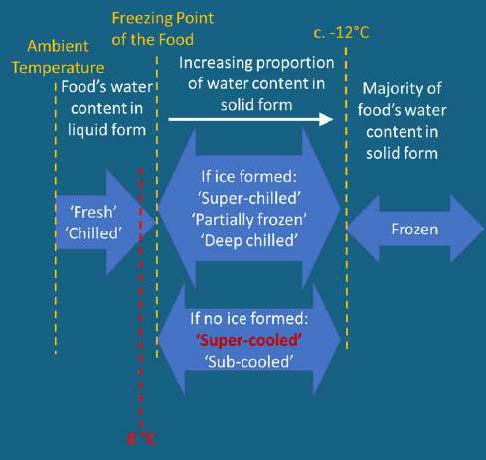

Unfortunately, there is a proliferation of terms (Figure 1) used to describe the temperature states of fish, and the techniques used to cool and store fish below zero degrees. For instance, there is no commonly agreed definition of terms in the temperature zone between 0°C and -12°C. The terms ‘super-chilled’, ‘deep-chilled’, ‘ultra-chilled’, ‘hard chilled’, ‘partially frozen’, ‘soft-frozen’, ‘super-cooled’, ‘sub-cooled’ or ‘under-cooled’ are used interchangeably to describe both rapid techniques to cool fish to temperatures below zero, as well as techniques designed to hold and transport fish at temperatures below zero. Super-cooling is defined in the International Institute of Refrigeration’s International Dictionary of Refrigeration as “Cooling a substance below the normal freezing point without start of solidification.” In our opinion this definition of supercooling should be used.

Super-chilling (often also described as ‘deep-chilling’ or ‘partial freezing’) is commonly confused with super-cooling. Although the temperatures used are similar, in the region of -2°C to -3°C, this technique still results in some ice being formed in the product (EFSA, 2020). While it is claimed that super-chilling doesn’t impact on the quality of fish, the formation of ice crystals within the fish are likely to have some effect on structure and perception (Sampels, 2014).

Figure 1. Some of the confusing fish temperature nomenclature between chilled and frozen

Trials demonstrate super-cooling benefits

Initial storage trials of vacuum-packed mackerel and haddock showed that they could be held stably in a super-cooled state at -2 ± 0.5°C for at least 13 days; and that cod and salmon could be held for at least 20 days, without any ice forming.

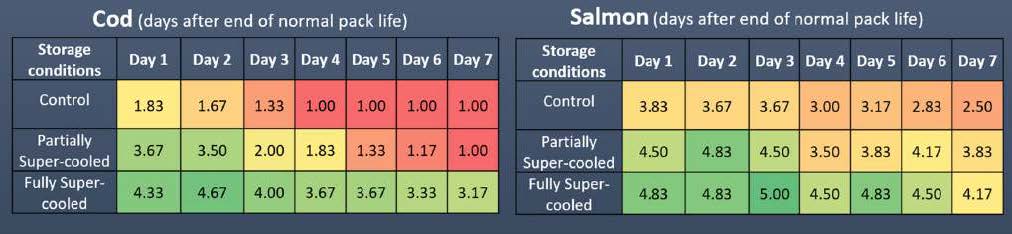

Initial organoleptic shelf-life assessment (Figure 2) of retail-packed cod and salmon indicated that shelf-life extensions of up to 5 –7 days longer than current chilled chain norms, could be achieved for super-cooled packs and still retain palatability. Even a short two-day period of supercooling during processing before dispatch into retail display/consumer storage could potentially extend storage-life by two days and four days (for cod and salmon respectively), demonstrating that super-cooling for even short periods may provide improved flexibility to producers and retailers along the supply chain.

The initial feasibility work demonstrated super-cooling of fish to be technically feasible and potentially offering meaningful commercial benefits. The utilization of super-cooling to extend storage life would also dramatically improve flexibility within the fresh seafood supply chain, and has the potential to reduce energy use and waste from harvest to retail. Potentially, super-cooling is versatile and could be used for different purposes. Fish could be super-cooled to keep it fresh during transport; to prepare it for better freezing; to maintain quality after thawing of previously frozen fish; to maintain quality during storage; and to keep it fresh during retail display and/or even domestic storage. Some domestic refrigerators with the facility to store super-cooled meat and fish have been marketed in recent years. The development of commercially viable super-cooling is likely to have a significant impact on the refrigeration equipment market as a whole.

Figure 2. Organoleptic assessment of acceptability of cooked taste

Having demonstrated the principle, an ongoing follow-up study, also funded by the UK Seafood Innovation Fund, is underway to investigate the challenges of practically implementing super-cooling into the seafood supply chain. This further work is in progress (Figure 3), but has established so far, that while spoilage bacteria (pseudomonads) do grow in super-cooled fish (as they also do in ‘deep chilled’/ ‘super-chilled’/ ‘partially frozen’ fish) their growth rate is much reduced. Moreover, super cooled retail-packed cod and salmon can be stored at -2°C with no ice formation in the flesh for up to 25 to 27 days before reaching bacterial upper limits associated with spoilage. This storage life is similar to that claimed for super-chilled/deep-chilled/partially-frozen fish at the same temperature (Midling, 2014; Eurofish, 2014) where ice has formed in the fish flesh. Although super-cooling maintains the freshness and quality of fish for a longer period than conventional chilling, once freshness or quality has been lost, they cannot be restored by super-cooling, so the initial microbial quality is still key to storage life.

Figure 3. Phase 2 trials

Commercial and legislative considerations

There are further challenges that need to be overcome before supercooling could be widely adopted, the primary of these being legislative. Legislation needs to be addressed to allow a more flexible approach to handling fish and fish temperatures to better reflect the requirements and capabilities of the modern fish cold chain. There is a binary mindset that fish can either be kept at 0°C (“the temperature of melting ice”) if chilled, or fully frozen at temperatures no warmer than -18°C; there is no in-between. While there are some moves away from this in some territories (EFSA, 2021), even revised regulations still appear unduly restrictive. In our opinion, this needs to change to allow a more flexible approach to how fish is handled to both benefit the industry and help provide the consumer with a greater choice of fish, with less waste, and better utilization of the earth’s precious resources.

The research is showing that the supercooling technique is possible, can extend shelf life, and reduce energy needs. However, the key to adoption are the commercial cost benefits, which vary through the supply chain. The value of each extra day of shelf life is difficult to determine as it varies as the ’ownership’ of the fish moves from harvest, through processing, and retail to consumption. It is likely that super-cooling will first be adopted into niche, more vertically integrated supply chains where the cost and benefit are experienced by the same business (or small chain of businesses).

In conclusion, our experimental works to date in super-cooling indicate that the technique has potential for extending the ‘fresh’ (no ice formed in fish) shelf life of cod and salmon by between 1 –5 days depending on the species and duration in the super-cooled state within the supply chain.

References

pp.

Eurofish (2014). Fresh fish keeps up to two days longer. https://eurofish.dk/freshfish-keeps-up-to-two-days-longer/

Fukuma, Y., Yamane, A., Itoh, T., Tsukamasa, Y. & Ando, M. (2012) Application of super-cooling to long-term storage of fish meat. Fish Science, 78, 451-461.

James, C., & James, S. J. (2009). -2 to -12°C, not chilled but not frozen. New Food, 12:2, 15-17.

Johansen, A.-M. (2022). NOK 1.5 billion to be saved on salmon transport. https://nofima.com/results/nok-1-5-billion-to-be-saved-on-salmon-transport/

Kang, T., Shafel, T., Lee, D., Lee, C. J., Lee, S. H., & Jun, S. (2020a). Quality retention of fresh tuna stored using super-cooling technology. Foods, 9, 1356.

Kang, T., You, Y., & Jun, S. (2020b). Super-cooling preservation technology in food and biological samples: A review focused on electric and magnetic field applications. Food Science and Biotechnology, 29, 303-321.

Liu, X. Y., Zhang, X. L., Wang, G. B., Mo, F. Y., & Zhang, X. R. (2023). Application of super-cooled storage of aquatic products: A review. International Journal of Refrigeration, 154, 66-72.

Midling, A. S. (2014). Super-cool salmon stay fresh for a month. https://norwegianscitechnews.com/2014/08/super-cool-salmon-stay-fresh-for-a-month/

Park, D. H., Lee, S., Byeon, Y. M., Kim, E. J., & Choi, M. J. (2022). Effect of super-cooling storage applied with stepwise algorithm for fishes (salmon and olive flounder) and its freshness during extended storage. Food Bioscience, 49, 101950.

Park, D. H., Lee, S., Lee, J., Kim, E. J., Jo, Y. J., Kim, H., Choi, M. J., & Hong, G. P. (2021).

Stepwise cooling mediated feasible super-cooling preservation to extend freshness

of mackerel fillets. LWT, 152, 112389.

Sampels, S. (2014). The effects of storage and preservation technologies on the quality of fish products: A review. Journal of Food Processing and Preservation, 39, 1206-1215.