Article II 1/2025 - ULVA VALUE CHAIN DEVELOPMENT FOR SUSTAINABILITY AND LIVELIHOODS IN INDONESIA

Sea grape is very popular in some parts of Indonesia, particularly in South Sulawesi and the northern coastal areas of Central Java; it is eaten fresh as a salad vegetable and is available from wild harvests as well as farmed.

Sea lettuce is also abundantly available in Indonesia, being harvested from the wild in the coastal areas of Sulawesi, Lombok and the southern coastal areas of the island of Java. The main species harvested is U. lactuca, and to a lesser quantity, U. reticulata, U. linza and U. compressa. Traditionally, harvesters collect Ulva along the coastal areas during low tide, sell it in dried form to local traders who then send it to processors/ traders/exporters supplying local and export markets for food, feed, fertiliser and pharmaceutical purposes.

Potential uses of Ulva

One of its important active ingredients is ulvan, a water-soluble polysaccharide which can be used as an antioxidant, antimicrobial pathogen and anticancer agent, as well as possessing a high phenol content. In addition to its nutritional value, U. lactuca can also be used for bioremediation because it has a high growth rate in a wide range of environmental conditions and is able to absorb nutrients from liquid waste arising from farming activities. Furthermore, as an edible seaweed, Ulva in Indonesia is used to make food products, including chips, flakes and sea vegetables; as a healthy salt source; and as a bio-stimulant (for example, a company in Bali uses harvested wild Ulva as a bio-fertiliser and bio-stimulant).

Reportedly, most of the dried Ulva exported from Indonesia is used as a feed ingredient in countries such as Vietnam. Considering its potential for various usages as food and non-food, the Global Quality and Standards Programme (GQSP) Indonesia, a project jointly implemented by UNIDO (United Nations Industrial Development Organization) and the Ministry of Marine Affairs and Fisheries (MMAF) in collaboration with private partners, supports the development of a sustainable Ulva value chain to protect biodiversity and improve the livelihoods of coastal communities in selected locations.

Sustainable farming trials

Ulva has been farmed and commercialised in some countries under controlled and intensive conditions. The challenge is how to develop farming systems for coastal communities, requiring low investment and appropriate technology. Several factors that affect its growth include water salinity and temperature as well as nutrients, light intensity, water movement and the microbiome in each site. The temperature determines the biochemical processes in the cell; salinity is related to osmotic pressure; light is closely related to the photosynthesis process to produce energy; and water movement is related to the process of nutrient absorption for cell formation. Fortunately, Ulva easily adapts to a wide range of environments, changing its morphological characteristics quickly in the process.

Farming Ulva lactuca in Indonesia has been tried on a small-scale in fiberglass, concrete, and tarpaulin tanks, mainly carried out by researchers of government R&D centres and higher education institutions. In trials, U. lactuca was found to have a relatively fast growth rate and under ideal conditions, it should increase in weight by 5–10 times within seven days after the seeds are stocked in the growing tanks. Furthermore, it is envisaged that a tank which can contain 10 tonnes of seawater and stocked with 10 kg seeds, will produce 50–100 kg of wet biomass in a week, or 200–400 kg of wet biomass per month.

To commercialise and up-scale Ulva farming, GQSP Indonesia, in collaboration with a researcher from the National Research and Innovation Agency (BRIN) and private partners, recently (October 2024) launched pilot projects in the Takalar district of South Sulawesi; the Gunung Kidul district of Jogjakarta; and the Buleleng district of Bali. Investment in the construction of all necessary production facilities (tanks, pumps, aerators etc.) was supplied by the private partners while GQSP Indonesia provides the technical assistance, starting from the construction of the production facilities and through the farming and monitoring stages.

Empowering communities

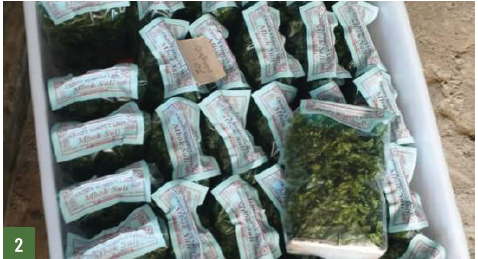

GQSP Indonesia, in collaboration with PT. Winner Perkasa Indonesia Unggul, has established a project to assist 50 small-scale women processors of Ulva chips from five beaches in Gunung Kidul, and at the same time to promote the farming of Ulva. The project aims to support the processors in improving their chip product quality and packaging as well as help them to obtain the necessary certificates to enable their products to access wider markets in modern retail outlets and through online platforms. Other major objectives were to showcase the possibility of farming to the locals as an alternative source of more sustainable income and better quality of raw materials; as well as reduce dependency on the wild stocks.

Since June 2024, capacity-building sessions have been provided for the selected small-scale processors, including training on processing and packaging technology; quality assurance; product development; diversification; value-addition and marketing as well as promotion. Research was carried out on enhancing the taste of the chips while retaining the distinctive, natural taste of Ulva; producing Ulva flour for various culinary applications; and producing Ulva flakes and other derivative products. Close technical guidance was also given, aimed at improving the harvesting methods for wild Ulva to achieve better yields and quality.

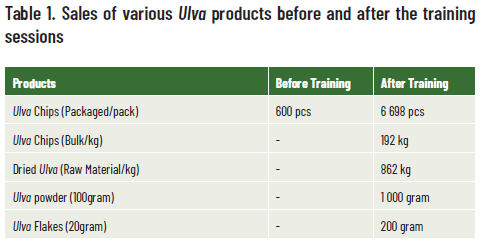

In the meantime, marketing and promotion efforts have been intensified on-line and off-line, including participation at national exhibitions, bazaars and joining on-line market platforms. As a result, various Ulva products (chips, flour and flakes) from these small-scale women processors have successfully been marketed outside of Gunung Kidul, including to Jakarta, Bali, Semarang, and other big cities in Indonesia. A comparison of the sales volume before and after the training is presented in Table 1. The total value of the sales after the capacity building is estimated at around IDR 110 million (USD 7 100), a sum that really meant a lot for the community.

The way forward

In addition to farming in tanks, trials will also be carried out with regard to farming Ulva in the outlets of shrimp farming ponds. The purpose is to make use of rich nutrients in the wastewater of shrimp farms to grow Ulva and at the same time to “clean” the wastewater before it is discharged. The Ulva harvested from the outlets can then be used as animal or fish feed. Farming Ulva in open sea water along the coastal areas is also being explored as an alternative, which might be cheaper compared to farming in tanks.